It's time to rethink the world. In cycles. Transparently. Consistently sustainable. Concern for the environment has been a firm part of the company DNA at OBJECT CARPET for 50 years. The manufacturer of designer carpets and floor coverings is regarded worldwide as a pacesetter for environmentally friendly innovations that raise ecology and recycling, as well as health and quality, to the next level. A decade ago, for example, carpets made of ECONYL® yarn – from recycled production waste and fishing nets – caused quite a sensation. But in the meantime, they have become, just like a second life cycle for floor coverings, a matter of course for every responsible manufacturer. Now OBJECT CARPET is once again pioneering a groundbreaking innovation that makes carpet-to-carpet recycling a reality. Starting in February the curtain will go up for NEOO – the first recyclable carpet made from just one material.

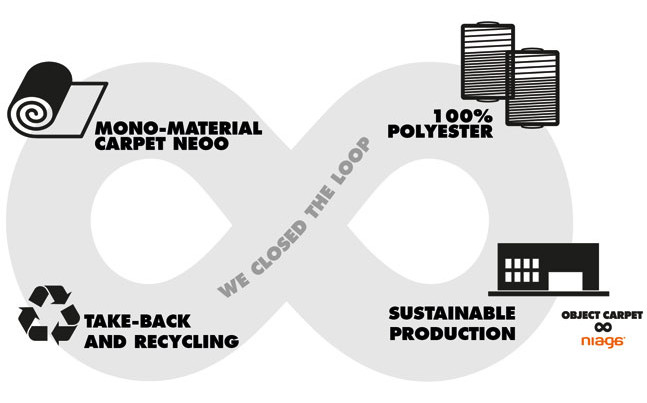

100% circular, 100% clean, 100% polyester: NEOO by OBJECT CARPET – the first infinitely recyclable carpet made of mono material. Designed for endless life.

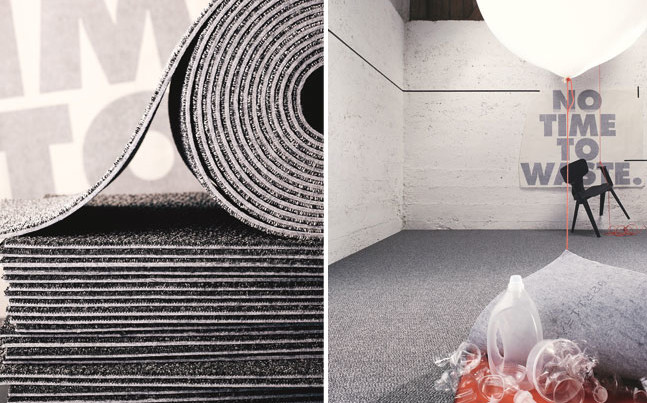

AGAIN AND AGAIN AND AGAIN AND AGAIN...

“Developing a recyclable, resource-saving and pure floor covering was one of the biggest challenges our company has ever faced,” says Lars Engelke, Managing Director for Production and Development at OBJECT CARPET. It took a lot of patience to work towards this goal. But he has always been driven by the vision of developing sustainable floor coverings. “Already 16 years ago, we made the decision to take a completely different path, despite the huge investment costs,” says Engelke. “As a family-run company, we are independent of investors and can determine our own course.” And for Lars Engelke, that course was clear from the very beginning: “sustainability! All the way down the line!” He has been consistently working on this and is pleased to have found a partner in Niaga® who was able to support OBJECT CARPET with the necessary technical and material expertise. The Niaga® (“again” spelled backwards) company from the Netherlands is part of the Covestro Group. They specialize in research on circular recycling and draw on experience from a wide range of industries. The outcome of this fruitful collaboration will celebrate its premiere in February 2023: NEOO – the new carpet from OBJECT CARPET! It is made from 100 % polyester and is ideally suited for the commercial property sector, offices and hotels. It is also easy to install, quick to clean and can go through a countless number of life cycles. “After eight years of joint development work, we are proud to present the first infinitely recyclable carpet,” Engelke points out.

COMPARING MONO CARPETS WITH CONVENTIONAL CARPETS

If we take a look at conventional textile floor coverings, we can easily see the great challenge OBJECT CARPET faced: they are often a mix of more than 30 materials. From yarn for the top layer to supporting materials and connecting elements such as latex or fillers for the reverse backing. These are irreversibly bonded together or can only be separated with a great deal of effort. NEOO is different: “our new development is made of only one material,” says Engelke. “NEOO is manufactured without fillers and processed with an innovative polyester adhesive. That means there are no other materials to be separated when it is no longer needed.” What is really special about this is that the new product has at least the same quality level as the source product.

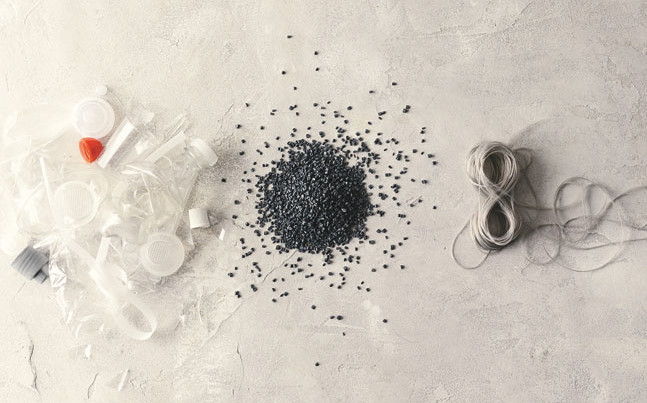

“For a recyclable carpet, we had to think differently from the ground up and break away from conventional processes,” says Lars Engelke, reviewing the last few years. The special hotmelt process bonds the surface material to the supporting material by applying the Niaga® polyester adhesive. After use, the mono carpet is melted down and extruded to produce new fibers. The recycling is just as simple and resource-saving. The carpet can be completely recycled over and over. Which, by the way, is four to five times more energy-efficient than producing new polyester.

The yarns of the polyester carpet are dyed using the environmentally friendly “solution-dyed” method. During this process, the dyes are added to the fibers while they are still liquid – i.e. before they are actually manufactured. The result is a high-performance weave that does not fade or stain. Another advantage: no water or gas is used during the coating process. This brings up to 95 percent energy savings compared to conventional production methods. A real technological quantum leap that takes the circular cycle to a new level.

JOIN US!

“With this, we are truly creating a change the industry. For the environment and for future generations,” sums up Lars Engelke. “However, recycling only works if many companies and consumers recognize the principle of the valuable raw material and are willing to return products to the cycle.”

This requires cooperation and close partnerships. We need customers, associations, networks, partners and recycling experts to participate in this special project and who also bring courage, interest and enthusiasm. With the aim of advancing its vision as quickly as possible, OBJECT CARPET is counting on transparency. Across different industries: “Everyone who is seriously interested in recycling can experience the sustainable creation process live in the Transparent Factory at our production location in Krefeld.” True to the motto: Join us!

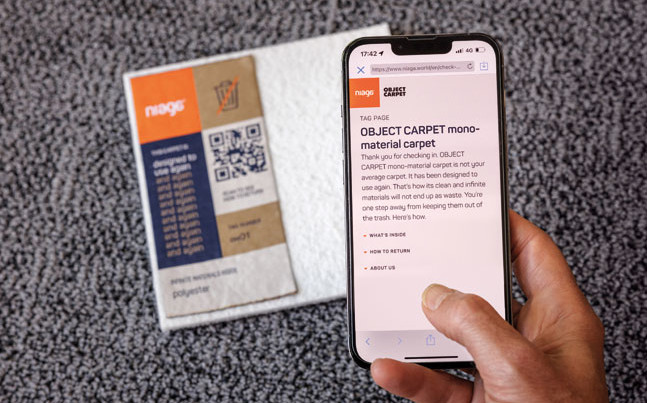

In the future, the Niaga®-tag – a marking attached to the product – will facilitate the process of taking back this mono-material carpeting. It draws attention to the fact that the product should not be disposed of and also provides important information on the composition of the material and the take-back process.

POLYESTER: A ROBUST MATERIAL FOR ETERNITY – FOREVER YOUNG

But why polyester? The answer is clear: polyester is a family of materials that can be recycled easily and without loss of quality. This makes the material the most recycled plastic in the world. This is because it retains its original properties and can therefore be recycled again and again for the same high-quality use. Everyone is familiar with polyester bottles (PET), which are continuously reprocessed by the packaging industry – without producing waste.

“Polyester is also ideal for floor coverings” the OBJECT CARPET Managing Director is convinced. “The durable material gives the carpet high elasticity, dimensional stability and resilience – at the same time it is extremely light-resistant, sound-absorbing and heat-insulating.” This makes NEOO a long-lasting, robust, and modern carpet for generations. Other arguments in its favor are its very good reaction to fire and remarkable acoustic effectiveness due to the new WELLTEX®CIRCULAR Acoustic Plus backing for tiles and broadlooms with a particularly strong structure. NEOO thus can enhance offices and hotels just as much as doctors’ and lawyers’ offices, companies, banks and other public buildings.

CONSISTENTLY SUSTAINABLE

“OBJECT CARPET is very committed to pursuing its green mission and thinks sustainability in an all-encompassing way – from development and production to marketing,” says Lars Engelke. The premium carpet specialist is known for its high-quality presentation and communication tools and also promises to make an impressive show for the premiere of NEOO. Starting in February 2023, all documents will be available to architects, planners and the specialized dealers.

Yvonne Schumacher

Press Director

yvonne.schumacher@object-carpet.com

You can find the entire press release on our GesK Press Lounge with additional image material in High-Res.