Ecology meets economy

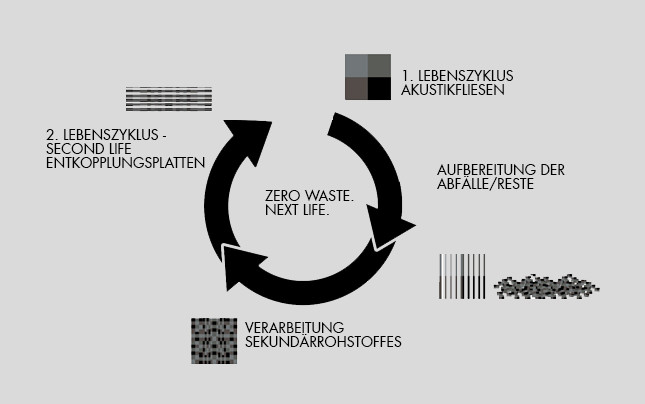

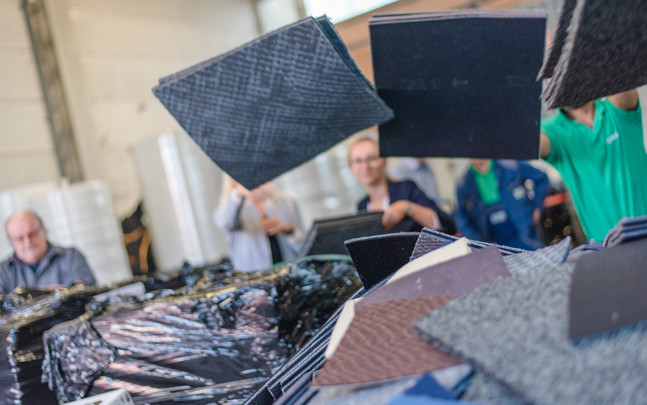

We have recognized the opportunity that lies in seeing waste as a raw material. By developing a future-oriented recycling process for modern carpets, OBJECT CARPET reconciles ecology and economy - avoiding waste is part of our history. For over 20 years, we have been systematically looking for reuse and recycling solutions for yarns, production waste and packaging materials. Because, of course, our manufacturing process is not entirely free of production waste. Machines have to be adjusted and test runs are needed, for example.

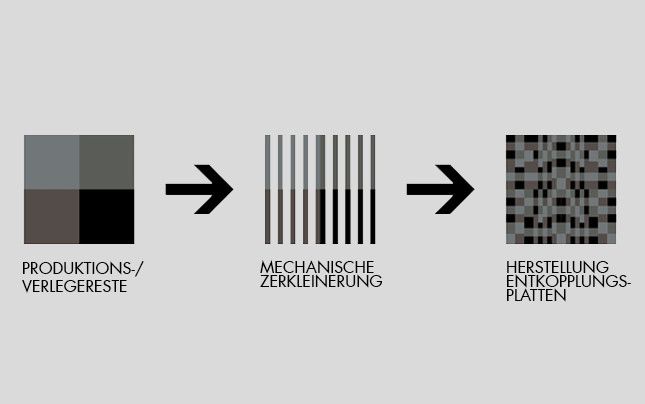

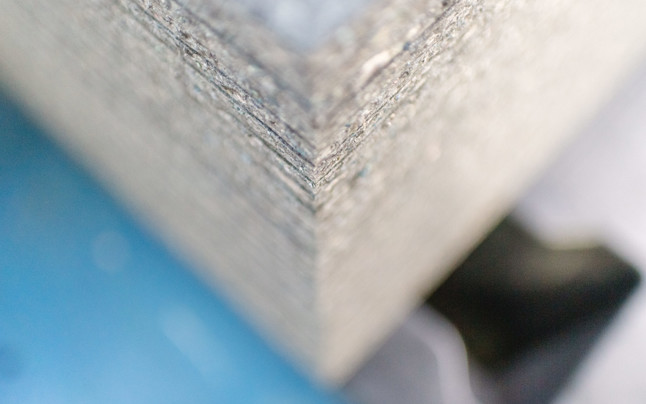

At the end of an average year, there are approx. 400 t of production residues, which we now use to create a completely recyclable second-life product: decoupling membranes for interior construction. The innovation: a construction component is turned into a new, useful building product for your sustainable renovation projects without any loss. Therefore, the composition of the carpets and tiles was designed to contain recyclable materials without any toxic chemical compounds. This also eliminates the need for chemical recycling. As a result, 75% of all products in the entire OBJECT CARPET collection are made from 100% recycled yarn as of today. Our acoustic tiles have already been free of bitumen, latex and PVC since 2017 and can be 100% recycled as a secondary raw material. This enables us to give the materials used a second life cycle.